Austria

Bitte mit Voranmeldung!

INIMITABLE CHARACTER CREATING UNMATCHED BEAUTY

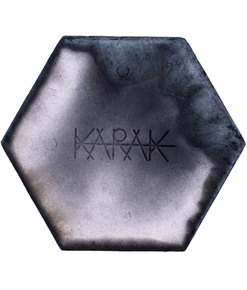

Surrounded by the Alps, KARAK ceramic tiles are created in a former spinning mill in western Austria’s Vorarlberg region. Nothing in the 150-year-old building was made for Raku — and yet everything here is as if made for.

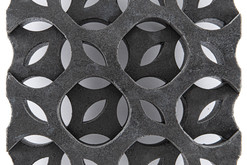

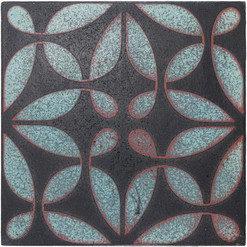

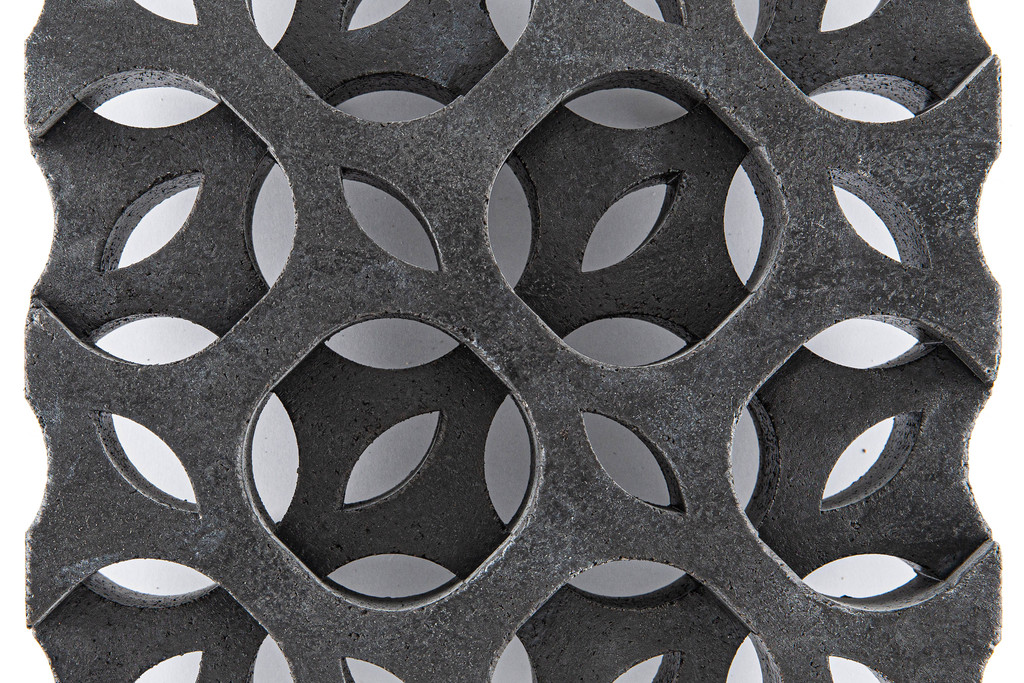

KARAK-tiles unite opposites into a well-grounded entity. Traditional Japanese Raku-firing technique meets contemporary ornamentation in the ceramic workshop in Vorarlberg, Austria. Karak produces goods exclusively to order in a small-scale, artisanal process. Adapted to architecture and individual customer requirements, each tile literally ‘walks through the fire’ and develops its own unique character. Regardless of whether you order one tile or one hundred, each tile is unique and can never be replicated. Whether for floors or walls, cladding for a tiled stove or as a room-dividing screen: The handcrafted process fills every surface with life.

Like the Raku process itself, KARAK was also born by chance, out of an idiosyncratic idea in 2007. Ceramic artist Marta Rauch-Debevec and rammed-earth builder Martin Rauch worked together to build the first self-supporting rammed-earth house in Vorarlberg. Marta also wanted special tiles for it — handmade and fired in the same ancient Japanese technique she used to create her sculptures and vases. With his passion for digital ornamentation, son Sebastian provided the equally extraordinary design: the Raku ornamental tile was born.

In 2015, Sebastian Rauch and his childhood friend Thomas Rösler assumed the art project and founded a company. In 2019, KARAK moved to the Klarenbrunn factory in Bludenz. There could hardly be a better place than an English brick building in the middle of the Alps for people making tiles by hand with conviction and passion.

Following the 700-year-old Japanese Raku technique, Karak tile manufacture is reviving a dying sort of craftsmanship in its most complex form: when fired, each tile is removed from the furnace at a temperature of 800 to 900°C, covered in sawdust and then submerged in cold water. It is the strongly operating elementary forces that create the tiles’ unique character.

RAKU

Following the 700-year-old Japanese Raku technique, Karak tile manufacture is reviving a dying sort of craftsmanship in its most complex form: when fired, each tile is removed from the furnace at a temperature of 800 to 900°C, covered in sawdust and then submerged in cold water. It is the strongly operating elementary forces that create the tiles’ unique character.

.

Jede Raku-Fliese wird circa 30 Mal in die Hand genommen, bis sie tatsächlich verlegt worden ist. Vielfach werden neue, individuelle Serien von Projekten und Personen inspiriert. So entstehen in enger Zusammenarbeit mit Auftraggeber*innen exklusive Objekte, die den Boden für sinnliche Räume legen.

Mit Unterstützung der D.E.S.I.G.N. Foundation

Image gallery